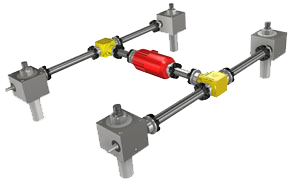

The MJ and BJ series with a cubic housing shape unite the idea of converting a rotary movement into an axial movement with the aesthetic exterior of the cubic housing to form a functional unit, through which the constructive basic idea of a simple and robust Screw jacks design was ideally realised.

Advantages

- Minimisation of the necessary components and maximisation of the effectiveness of these components

- Relatively large lifting and moving forces can be realised in the smallest of spaces

- The spindle is guided through the housing

- The cubic housing shape makes attachment to existing construction elements simple