The LinearChain – an innovative element in drive technology

LinearChains are an important component in linear drive technology. They develop their real strength where other products such as linear drives are ruled out for reasons of space. In drive technology, loads are usually moved by pulling or pushing. If you use linear drives they can do both: pull and push. The LinearChain can also do both, even though it is a chain. You will now see how that works.

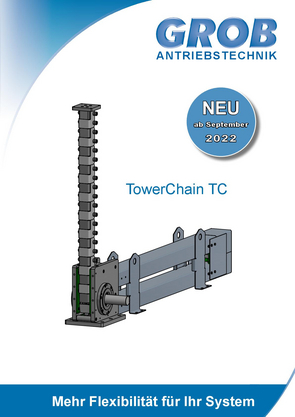

How the LinearChain works

It consists of specially formed, high-precision mechanical chain links. The chain links interlock with one another continuously and positively. The special feature of the LinearChain (as opposed to a "normal" chain) is that it works in both directions – it can pull and "push".

In the drive housing of the LinearChain is a gear wheel that engages in the chain and moves it link by link – both forwards and backwards. The chain itself has two loose ends. The load which is to be moved is attached to one end. The other end can be guided freely and is usually rolled up in a storage device. This saves an enormous amount of space and is the main advantage of the LinearChain. If you were to work with a "normal" linear drive you would need much more installation space for the spindle stroke.

This is how the LinearChain works when it "pulls"

Now it works like a normal chain and the links can be wound up in one direction and stored in a magazine, thus saving space.

How is the LinearChain guided?

You have two possibilities: either it runs over a sliding surface or in a guide rail. The choice of guide depends on the pushing force, the stroke length and the speed of movement. Guidance is necessary from a certain stroke length to prevent the LinearChain from buckling.

These are the typical applications for the LinearChain

- The drive in a lifting table

- Stage platforms

- In tool and material handling

- In warehouse logistics

- For feeding tempering furnaces

- In refrigeration systems

- In modern buidling systems

- In conveying systems

- When changing the tools on metalworking presses

- In driverless transport systems

- In the ContainerMover