Advantages

- Simple and effective solution in comparison with hydraulic and pneumatic systems

- The bevel gear transmission makes high lifting speeds and a high duty cycle possible

- A defined load can be moved to an exact position at a preset speed

- In the case of the gear reductions 2:1 and 3:1, the variable positioning of the drive shaft renders an additional transfer gearbox unnecessary, so that several high-speed linear drives can be combined into one lifting unit

- They can exert the same forces in both the pushing and pulling direction

- Many technically ideal and economically interesting solutions can be realised with our modular construction kit concept

- High-speed linear drives are valued by design engineers as standard machine elements

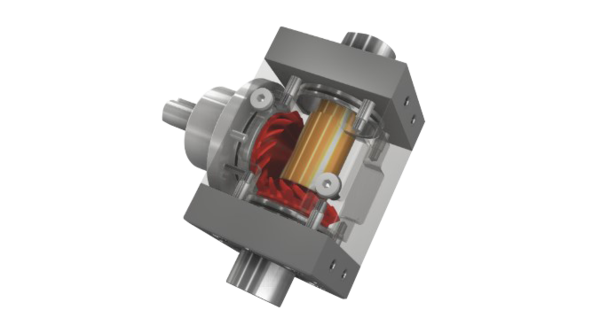

High-speed Screw jacks – when high lifting speeds are required

High-speed Screw jacks are a special form of Screw jacks. They allow higher lifting speeds than the usual Screw jacks. This is made possible by a low gear reduction, stable design, optimised lubrication conditions, variable thread pitches and permissible input speeds of up to 3000 rpm. The arc-toothed, single-stage bevel gear sets are designed for high running smoothness and load capacity and thus enable smooth and stable running of the spindle with high input power.

High-speed Screw jacks are genuine all-rounders in linear drive technology. Because of their versatility there is hardly any application where they can't be used as a drive element.

- As a basic version: the output bevel gear is connected to a trapezoidal threaded nut (selectively also with ball screw nut). The nut, which is made to rotate by this, exerts an axial force on the spindle. Now either the spindle head is fixed on the factory side or the spindle is secured against rotation on the gearbox side. A linear lifting movement is thus generated and the lifting spindle thereby travels through the linear drive.

- As a travelling nut version: The output bevel gear is positively connected to the threaded spindle and thus transmits the rotary movement. The travelling nut sits on the threaded spindle. It is secured against rotation by the load. The rotating threaded spindle thus sets the travelling nut in a linear lifting motion.

You have the choice between two drive versions and three sizes as well as various reduction gearings and spindle pitches

The correct choice of drive for your application depends on different factors: on the demanded payload, speed, duty cycle, load case and available space. In principle there are two versions:

These standard sizes of high-speed Screw jacks are available

- KH090 with a maximum static load of 15 kN

- KH140 with a maximum static load of 40 kN

- KH230 with a maximum static load of 90 kN

Realisable transmission ratios are 1:1. 2:1 and 3:1. Up to three further output gear wheels can be mounted with the transmission ratios 2:1 and 3:1.

What might also interest you

Detailed information on high-speed Screw jacks can also be found in our reference book on pages 116-121.

You're not sure which type of high-speed Screw jacks is the right one for your application? No problem – just call us directly and we'll help you to find the right solution. Phone +49-(0)7261-92630.